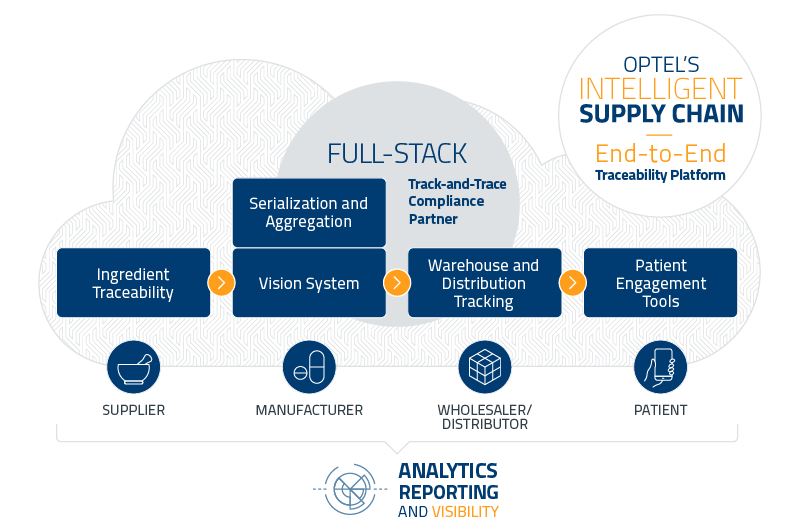

FULL-STACK TRACK-AND-TRACE SOLUTIONS

TRACEABILITY SYSTEMS DESIGNED TO MEET YOUR NEEDS

As the pharmaceutical industry continues to adapt to the new challenges and increasing demand for supply chain security, companies must also equip themselves with the tools to protect their brand while maximizing operational intelligence.

OPTEL has become the recognized global leader in track-and-trace technology, with more than 30 years of experience in the pharmaceutical industry and more than 6,000 solutions deployed around the world.

OPTEL’S TRACK-AND-TRACE TECHNOLOGIES

Manufacturer

Serialization, Aggregation and Vision Inspection- Cost-effective turnkey solutions

- Full-stack technologies from L1 to L5

- Meet regulatory requirements from most countries

- GS1 standards

Wholesaler and Distributor

Warehouse and distribution tracking- Increased operational intelligence

- Achieve regulatory compliance

Consumer

Patient Engagement Tools- Complete supply chain visibility and transparency

OPTEL’S TRACK-AND-TRACE TECHNOLOGIES

OPTEL’s full-stack track-and-trace technologies can help your business comply with all worldwide regulations while guiding you along the next crucial steps to go beyond compliance toward a more intelligent supply chain.

Optchain™ for Advanced Therapy Medicinal Products

Track-and-Trace Solutions

Pharmaceutical IndustryMORE THAN 35 YEARS OF EXPERTISE

MARKET-LEADING TECHNOLOGY BASED ON INNOVATION, PERFORMANCE, INTEROPERABILITY AND RELIABILITYCATEGORIES THAT MAY INTEREST YOU

Wholesalers and Distributors

Serialisation solutions for EU FMD compliance

CMOs and CPOs

Serialization solutions to help achieve compliance

Manufacturers

Track-and-trace solutions to help comply with all upcoming regulations

3PLs and Repackagers

Achieving compliance without disrupting the supply chain

Medical Devices

Turnkey vision inspection and traceability solutionsSOLUTION FINDER

FIND THE RIGHT SOLUTION FOR YOU

Aggregation Solution

Aggregation takes you beyond unit-level traceability to see the whole picture

Anti-counterfeiting

Stop counterfeiting, protect your brand and gain greater consumer confidence

Battery Traceability

Contribute to a better environment through battery traceability

Carbon Tracking

Measure and track your environmental footprint across your supply chain

Digital Product Passport (DPP)

Find out about OPTEL’s approach to overcoming the challenges associated with the European Union’s upcoming Digital Product Passport. Learn how we do it differently.

Engagement Programs

Engage directly with consumers to optimize your marketing programs

EUDR Compliance Simplified

Optchain’s EUDR software links commodities to their production plots using data capture tools tailored to your supply chain, operations and processes.

Food Safety Compliance

Improving food safety and integrity through supply chain traceability

Inventory Tracking and Planning Solution

Manage your inventory like never before: real-time visibility on asset inventory levels, geolocation and expired date tracking

Line Automation

Production Line Automation Solutions: from the case packer to the end-of-line Cobot Palletizer, discover OPTEL’s high performing and turnkey automated line solutions.

Operational Efficiency

Optimize your production efficiency with strong analytics and reliable, real-time data for the agribusiness

Operational Performance

Optimize your production efficiency with strong analytics and reliable, real-time data for the CPG, food and beverage industries

Optchain for ESG Compliance and Traceability

Optchain is a supply chain platform focused on ESG compliance, automating data collection, improving visibility, and delivering insights.

OPTCHAIN for CBAM Compliance

Optchain offers an all-in-one solution for CBAM compliance. Track scope 1, 2, and 3 emissions and submit XML reports.

Product Authentication for Metals and Minerals

Authenticate any product, any time, anywhere for total consumer confidence and regulatory compliance

Product Quality

Traceability for visibility, precise and more efficient recalls, and raw-material traceability

QR Code Verification

Drugs Rule 2022 in India: Discover OPTEL’s QR Code Verification Solution

Traceability for the Residual Material Industry

Know the where, when and how of all your material disposal

Responsible Sourcing

Trace materials back to the source to ensure and prove sustainability

Responsible Supply Chain – Metals and Minerals

Ensure metals and minerals are responsibly sourced and environmentally sound

Reusable Packaging Management

Trace and monitor your reusable assets from manufacturing to end user and back

Serialization Solution

Serialization is the first step in the traceability journey. OPTEL delivers scalable pharma solutions for global compliance and end-to-end visibility.

Site Level Solutions (L3)

Manage your plant-level serialization operations with the latest technology

Sustainable Supply Chain

Ensure ingredients and raw materials are responsibly sourced and environmentally sound

Tax Management Solutions

OPTEL offers a scalable and modular Tax Management Solution that uniquely marks, inspects, tracks, traces and validates your products throughout the supply chain. Comply with regulations, mitigate counterfeit, and gain access to valuable data.

Track-and-Trace Solutions for the Pharmaceutical Industry

Gain supply chain visibility and assured traceability with audits and certifications

VerifyBrand™ Supply Chain Integrity Solution

Discover OPTEL’s VerifyBrand™ Real-Time Serialization and Traceability software for Compliance, Product Authentication, Brand Protection and Inventory Optimization.

VerifyBrand™ for the Pharmaceutical Industry

VerifyBrand™ is an essential tool to comply with most of the world’s pharmaceutical regulations

Vision Systems

Discover OPTEL’s unmatched Vision Systems with AI capabilities. Our Visions Systems can inspect any product with high accuracy to ensure product safety and quality.

Warehouse Management Solution

Manage your distribution and warehouse serialization process