MEDICAL DEVICE INSPECTION SOLUTIONS

You’ve invested time, money and energy into quality assurance while doing your best to keep costs low and productivity high. But is your quality system doing its best for you?

Manual packaging and handling procedures, outdated data-management systems and the constant risk of human error can too easily compromise the quality and integrity of medical devices, putting patient health and safety at risk.

As the industry moves toward more stringently controlled, connected medical devices, OPTEL’s innovative, turnkey vision system and digital traceability solutions can help you optimize safety and security with minimal disruption to precious productivity time.

OPTEL’S MEDICAL DEVICE SOLUTIONS INCLUDE:

Quality Assurance and False Rejects

On average, one company per year sees a 10-percent drop in share price after a single, major quality event, and the risk of long-term reputational damage is real.

Recall Reduction and Management

Non-routine quality events such as recalls cost the industry an average of up to $5 billion per year, yet many manufacturers still rely on monolithic systems that actually slow their ability to track and manage recalls.

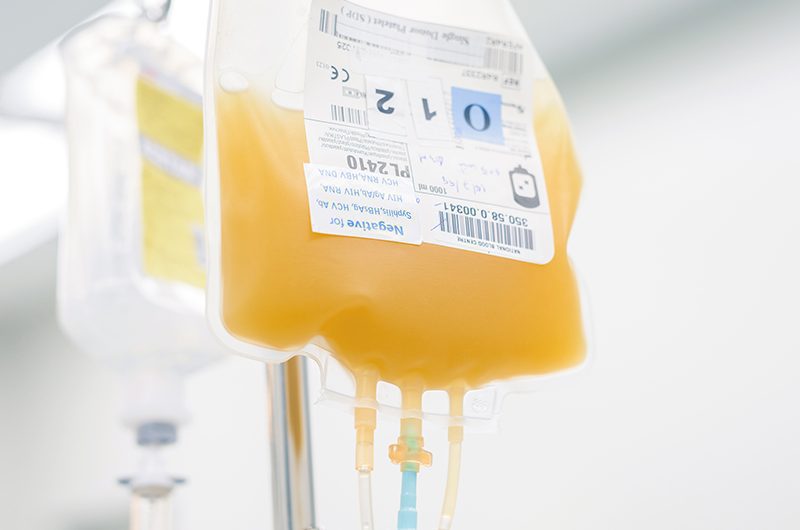

Tracking Devices Up to the Patient

In the event of a recall, tracking medical devices up to the patient is critical, yet some manufacturers don’t even have a warehouse management system (WMS) in place to tell them where their product is in the supply chain.

Complying with UDI Regulations

Develop a future-proof UDI strategy and be prepared to adapt to evolving requirements across countries and regions worldwide.

In the wake of media reports about medical device recalls, defects and government oversight, many regulatory bodies are now drafting or enacting tougher controls over medical devices. Failure to comply is not an option.

MORE THAN 30 YEARS OF EXPERTISE

MARKET-LEADING TECHNOLOGY BASED ON INNOVATION, PERFORMANCE, INTEROPERABILITY AND RELIABILITY

KIT AND TRAY INSPECTION

In addition to detecting component presence, our systems use metrology to detect millimetric differences in the general attributes of the items contained in kits and trays.

Contact Us

LABELING AND PRINTING INSPECTION

Inspect printing on packaging materials, including flexible web, Tyvek, paper, foil, pouches and more. Detect label presence and characteristics, artwork and variable data, barcodes and grading to comply with.

Learn more

Medical Device Counterfeiting

Case StudyDISCOVER THE RIGHT TRACEABILITY SOLUTION FOR YOUR INDUSTRY

Pharmaceutical

Track-and-trace systems for the pharmaceutical industry

Wholesalers and Distributors

Serialisation solutions for EU FMD compliance

Manufacturers

Track-and-trace solutions to help comply with all upcoming regulations

CMOs and CPOs

Serialization solutions to help achieve compliance

3PLs and Repackagers

Achieving compliance without disrupting the supply chain

Hospitals and Pharmacies

Solutions for healthcare providers and pharmacies