Semi-Automated Print Station

The Semi-automated Print Station: Fastest Solution to implement Serialization and Aggregation for low volume production.

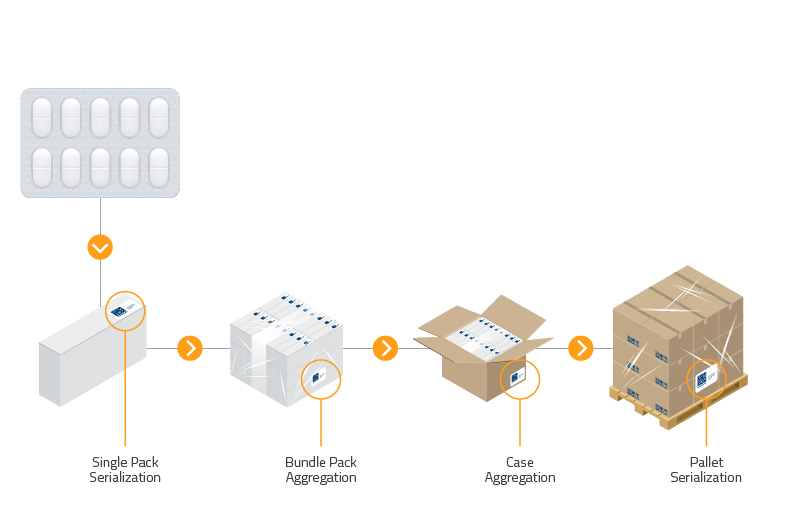

If serialization was the beginning of pharmaceutical track and trace then aggregation isn’t the end but it’s the next logical step to enhance supply chain security and traceability.

Those choosing aggregation today are moving ahead of their competition in terms of efficiency, security and traceability while removing many barriers to new markets.

While aggregation is key to patient safety and therefore a secure pharma industry, this process comes with new challenges.

These are the reasons why you need to choose your aggregation provider wisely and make sure they provide true expertise and support during the implementation process.

Many pharmaceutical companies are experiencing cost savings from improvements along with the following:

Discover our Supply Chain Integrity Solution

Semi-Automated Print Station

The Semi-automated Print Station: Fastest Solution to implement Serialization and Aggregation for low volume production.

CartonTracker

Automated serialization solution with great stability for printing and inspection, and that has an integrated ejection system

LineMaster

Software embedded in the line that records all serialization and aggregation events at the packaging level

PackStation (FMP)

Manual aggregation solution that can also serialize any level of packaging

PackStation (SAP)

Semi-automatic solution designed to read serial numbers and add them to shipping cartons

CLTracker (TE)

Solution developed for implementation in sealing units or tamper-evident features that serializes and inspects data

BottleTracker

Solution that inspects and adds bottle labels without interrupting the production flow

BundleTracker

Solution that makes the aggregation of grouped products. It checks product count and status while rejecting defective packages

PalletMaster

Aggregation solution that identifies and checks boxes and pallets with cameras and/or barcode readers for the central palletizing area

Association Station

Solution that checks serialized products and facilitates aggregation into secondary packages

Kompano

Solution that manages the serialization of products in the warehouse: prints labels, reworks, sending and receiving

Vision Systems

Discover OPTEL’s unmatched Vision Systems with AI capabilities. Our Visions Systems can inspect any product with high accuracy to ensure product safety and quality.

Serialization

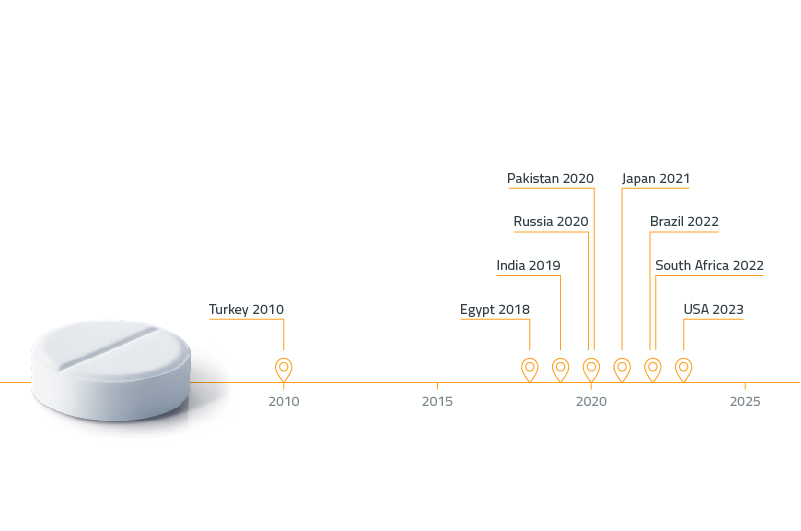

Serialization is the first step in the traceability journey. OPTEL delivers scalable pharma solutions for global compliance and end-to-end visibility.

Line Automation

Production Line Automation Solutions: from the case packer to the end-of-line Cobot Palletizer, discover OPTEL’s high performing and turnkey automated line solutions.

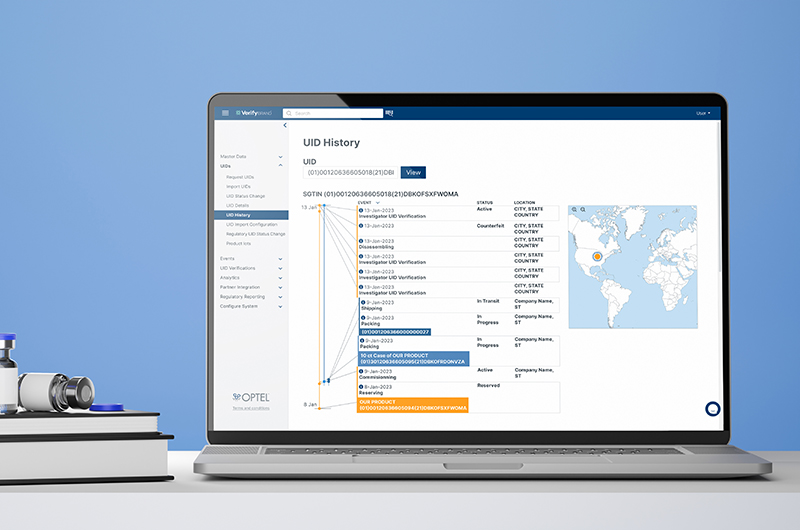

VerifyBrand

Discover OPTEL’s VerifyBrand™ Real-Time Serialization and Traceability software for Compliance, Product Authentication, Brand Protection and Inventory Optimization.