In October 2022, the World Health Organization (WHO) officially launched its Global Strategy for Food Safety 2022-2023, which will guide members in planning, implementing and monitoring national action plans to reduce foodborne illnesses. According to Food Safety Magazine, the strategy will also contribute to making food systems safer by promoting global cooperation—between countries and interconnected supply chains.

The strategy’s targets for 2030 are ambitious as the WHO works to bring government institutions, UN agencies, educational institutions, NOGs, the private sector, and public health and food safety experts together. The aim is to reduce the burden of foodborne illnesses by slashing the number of foodborne diarrheal diseases by 40% in vulnerable populations. The strategy also has a goal to achieve 100% of functional coordination mechanisms to manage foodborne events and boost laboratory capacity for surveillance.

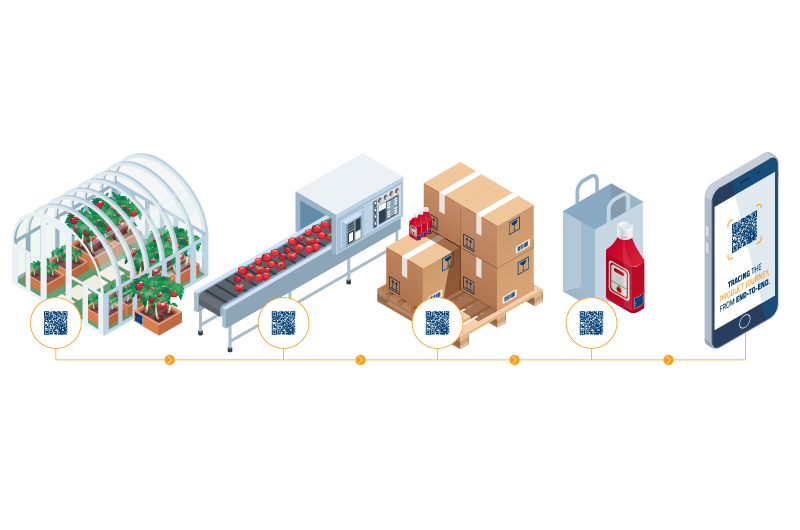

While there are five main priorities laid out in the overall strategy, one key area of focus is critical for the strategy’s overall success: that each WHO member establishes means to improve their respective nation’s food supply chain information and regulations concerning food traceability.