STEPS OF SERIALIZATION AND TRACEABILITY FOR PHARMACEUTICAL INDUSTRY

The pharmaceutical industry has no shortage of challenges – regulatory scrutiny, patent cliffs, R&D productivity, and most of all, the complex supply chain. Drugs and medications go through several changes of hands: from manufacturers to repackagers, to the dispensaries, and finally, to the patients. This long chain facilitates the easy entry of counterfeit drugs and the diversion of legitimate ones.

Cost-cutting pressures, demand for generics, drug shortages and increased online buying have further fuelled the sale of counterfeit drugs.

The problem is especially severe in former Soviet republics, where the presence of counterfeit drugs in the supply chain is more pronounced than in other countries. The share of counterfeit drugs in the Republic of Kazakhstan is estimated at 10-12%, meaning one out of 10 drugs sold is fake.

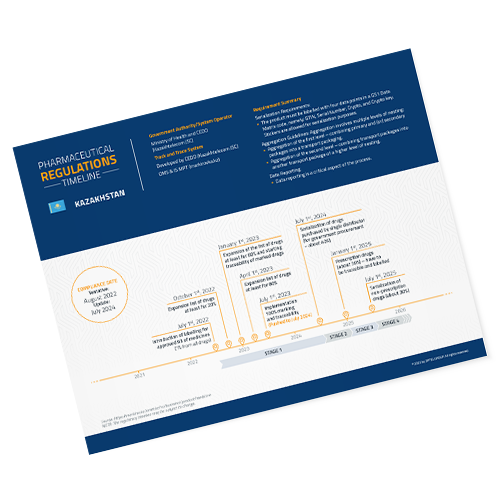

To counter this predicament, the government of Kazakhstan has planned to introduce mandatory labelling of drugs and a tracking system by 2023. Here’s everything pharmaceutical manufacturers and packagers in Kazakhstan need to know about track-and-trace developments.