InspectProof

Automated vision system that verifies product information, such as validity, tamper-evident cap and seals, labels, presence of components, etc.

Unit dimensions, shape, color, direct product marking (embossed codes)

Component presence, shape and dimensions

Packaging integrity, seal inspection, inserts, topserts and sideserts, cap and tamper-evident seals

Label presence, orientation, print positioning and quality, artwork and variable data, barcodes and grading; verification of characters (OCV/OCR on lot, expiry date, DIN/NDC, label ID and serial number); online grading of linear barcodes and 2D codes (DataMatrix) according to ISO/IEC standards.

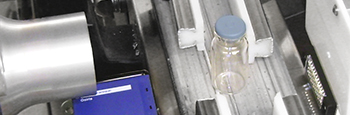

OPTEL’s powerful Vision Systems for Vial Inspection ensure your products meet the highest safety and quality standards.

From Vision Systems to Operational Intelligence: a Logical Evolution

At OPTEL, we set out to do something no one had done before because we envisioned a future where every aspect of production could be tracked, traced and communicated through shared data.

Everything You Need to Know About Pharmaceutical Track-and-Trace Systems

OPTEL helps pharmaceutical companies comply with traceability regulations

InspectProof

Automated vision system that verifies product information, such as validity, tamper-evident cap and seals, labels, presence of components, etc.

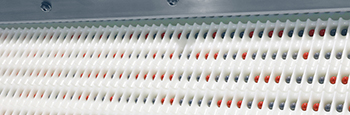

BlisterSafe

Solution that checks pills and capsules in blister pack packaging lines

CountSafe (Electronic Counter)

Inspection and rejection system that provides inspection accuracy and efficiency to electronic counters

CountSafe (Slat Counter)

Automated visual inspection solution designed to detect wrong color, missing items, broken products, foreign objects, etc.

VialSafe

Automated visual inspection solution for cap, crimp, rubber stopper, label, fill level, etc.

Serialization

Serialization is the first step in the traceability journey. OPTEL delivers scalable pharma solutions for global compliance and end-to-end visibility.

Aggregation

Aggregation takes you beyond unit-level traceability to see the whole picture

Site-Level Solutions (L3)

Manage your plant-level serialization operations with the latest technology

VerifyBrand™ for the Pharmaceutical Industry

VerifyBrand™ is an essential tool to comply with most of the world’s pharmaceutical regulations