BAHRAIN’S NHRA TRACEABILITY REQUIREMENTS FOR PHARMACEUTICALS

Approximately two billion people worldwide lack access to necessary medication and vaccines, according to the World Health Organization. Unfortunately, such a vacuum is often filled with falsified or substandard products.

The problem is exacerbated primarily by two factors. Firstly, healthcare supply chains have become too complex. Today, it’s possible for a product manufactured in one country to be packaged in another country and sold in a third. Secondly, the growth of e-commerce has made it easy for consumers to purchase “medication” online, often from unauthorized sources.

Counterfeit drugs can harm not only the user’s physical and mental health, but also their financial health, and erode their trust in the healthcare system.

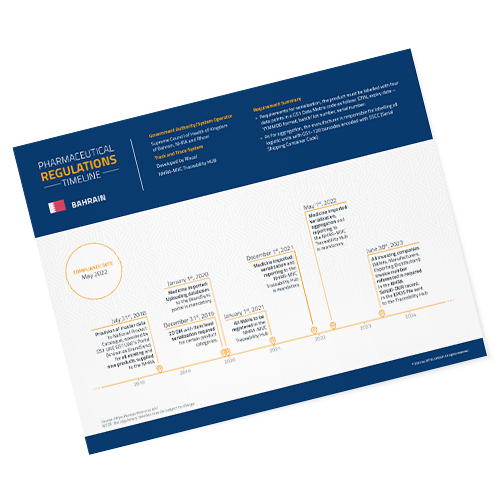

Fortunately, many national governments have taken active steps to address the issue. For instance, the Kingdom of Bahrain has pledged to create a complete track-and-trace system to curb the growing problem of drug falsification.

Pharmaceutical manufacturers or packagers that are based in Bahrain or have trade relations with the country need to know about the new National Health Regulatory Authority (NHRA)’s track-and-trace guidelines.

ROLE OF THE NHRA IN COMPLIANCE

The NHRA is a licensing body in Bahrain that decides whether a manufacturer is fit to produce and sell drugs. Individual manufacturers have to go through rigorous NHRA checks to sell their medicines. Professional healthcare workers also have to acquire an NHRA license to set up their practice, and the organization oversees clinical trials.

Recently, the NHRA has been working to develop an end-to-end track-and-trace system to deter drug counterfeiting.

WHAT IS THE NHRA TRACEABILITY HUB?

To realize their vision of end-to-end traceability, real-time transparency, accountability, and verification, the NHRA devised a data repository and track-and-trace application known as the NHRA-MVC traceability hub.

Pharmaceutical manufacturers and intermediary vendors must submit traceability and serialization information to the hub to facilitate enhanced product visibility and to protect the integrity of the supply chain.

With such a system in place, the NHRA and supply chain stakeholders will be able to:

- Accurately detect counterfeits

- Eliminate medication errors

- Ensure enhanced traceability

- Initiate faster product withdrawals and recalls

- Facilitate real-time information flow between stakeholders

So, how does it help supply chain stakeholders? Distributors, manufacturers, importers and others must complete the technical onboarding process to validate their readiness in sharing transactional information. They must send records of transactions to the traceability hub, such as:

- Receiving a shipment of serialized medicine into stock

- Packaging (aggregation of cartons to cases and cases to pallets)

- Shipping products to various dispensers (hospitals, clinics, pharmacies)

Though this adds an extra step to the process, it will help the pharmaceutical supply chain in the long run. How? Easily accessible data facilitates package location, inventory planning, demand forecasting, recall effectiveness and more.