35

Years of Expertise

6000

Systems Installed Worldwide

25B

Products Tracked Per Year

24 / 7

International Tech Support

96 %

Satisfaction Level Of Service

Discover our end-to-end traceability solutions

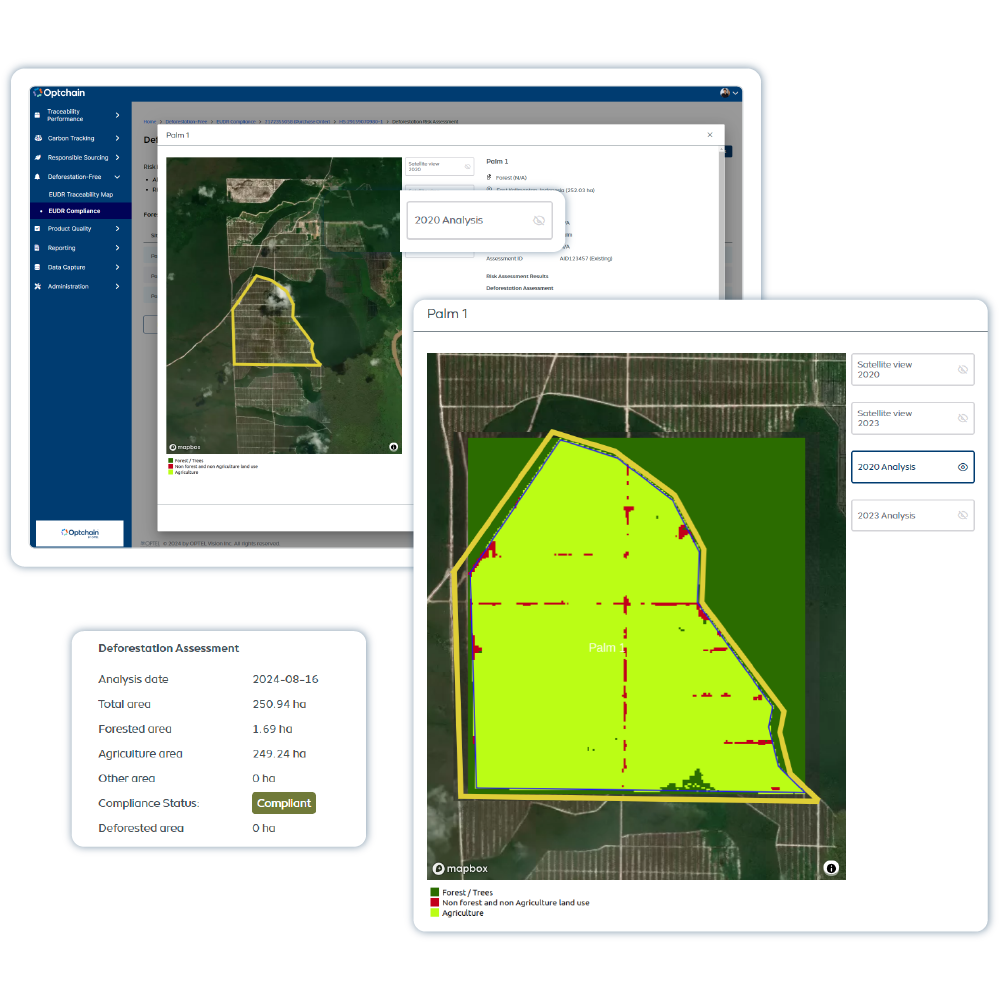

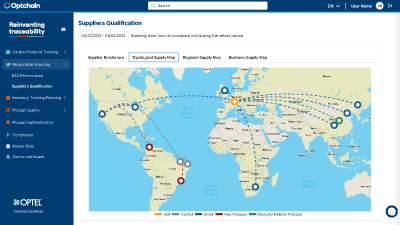

ESG TRACEABILITY

Optchain is a supply chain sustainability platform that ensures ESG compliance and full product life cycle visibility. Its modules cover regulations like EUDR, DPP, CBAM, CSRD, CSDDD and more. Optchain also tracks carbon emissions across supply chains, helping businesses measure, monitor, and reduce their environmental footprint

Discover Optchain™

TRACK & TRACE AND INSPECTION SYSTEMS

Site-level serialization and aggregation hardware solutions to optimize line performance and ensure track-and-trace excellence with AI-integrated vision systems.

Discover TrackSafe

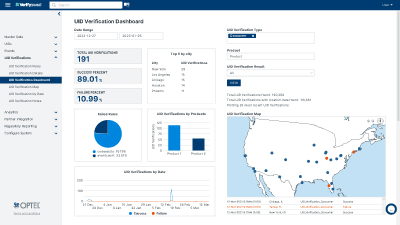

SUPPLY CHAIN INTEGRITY SOLUTION

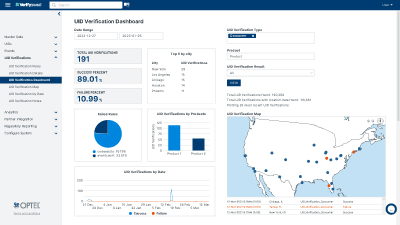

VerifyBrand™ is a real-time serialization and traceability software ensuring compliance, enhancing brand protection, authenticating products, and optimizing inventory.

Discover VerifyBrand™