Not everything is doom and gloom when it comes to recycling lithium-ion batteries for EVs.

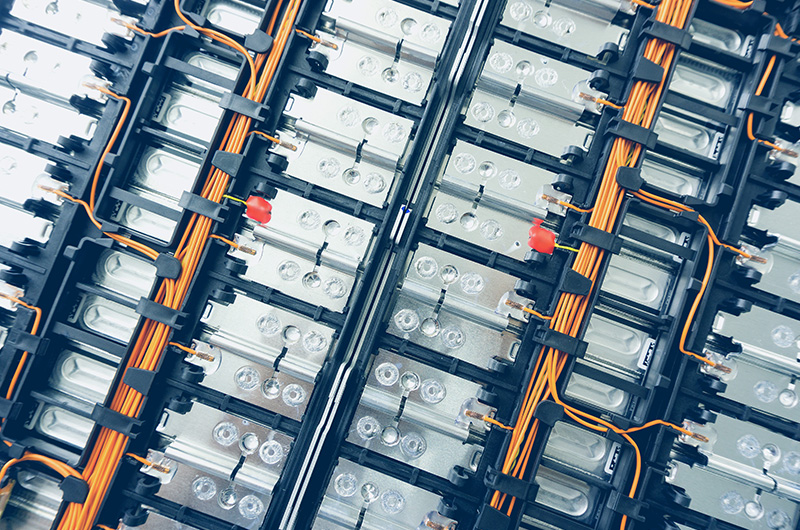

With the boom in EVs and the batteries that power them, mineral demand is set to skyrocket as well. Lithium, cobalt, nickel, and copper are all minerals used to make lithium-ion batteries; the vast majority are sourced from mines in Russia, the Democratic Republic of Congo, and China where environmental stewardship and human rights are often lax.

Moreover, rising demand for minerals could also result in supply shortages and huge price swings, according to some experts. This is leading manufacturers to experiment with new blends of raw materials, such as low-cobalt or cobalt-free batteries. Research is also underway to remove nickel as well. However, the EV industry is far from completely irradicating the minerals required for lithium-ion batteries.

Mounting pressure from industry stakeholders is forcing battery- and automakers to adopt more sustainable alternatives in sourcing materials. And better recycling may be very well the answer.

New techniques that foster chemical-free and more direct, scalable recycling recover more materials from lithium-ion batteries that have reached the end of their first useful life. These new approaches to recycling batteries could inevitably reduce the need to refine and transport new minerals. Based on some forecasts, recycled minerals could supply up to 50% of those needed for new batteries by 2040.

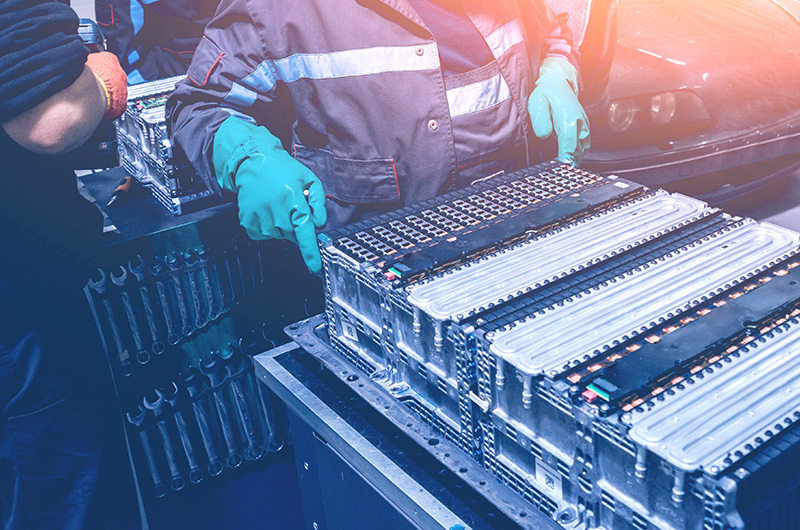

When lithium-ion batteries attain the end of their useful life in EVs, they often still keep approximately 2/3 of their energy storage. As a result, they could also be repurposed for use in applications that require lower power levels or even for backup storage for renewable energy, such as solar or wind farms.

Yole Development, a consulting firm in Europe, projects that the “global value of the recycled materials sector for lithium-ion technologies will grow at a CAGR of 25% between 2020 and 2025, with a total market value close to $1.2 billion after the five-year period alone.” By 2040, that figure is estimated to be as high as $24 billion, which underscores the tremendous opportunity for EV battery recyclers—and manufacturers.

Tesla announced in 2020 that it was planning to implement battery recycling capabilities at its Gigafactory in Nevada. The plant is being organized to extract minerals, including cobalt and copper, so that they can be reintroduced into the value chain. And this is just the beginning.

In sum, opportunities abound to create a more viable and sustainable circular economy with EV batteries.