WHEN CHALLENGES MEET OPPORTUNITIES

With a constantly gorwing population, the agrochemical industry faces unprecedented pressure to meet the rising demand for agricultural products.

This increased burden has pushed the stakes higher, underscoring the paramount importance of robust traceability systems. These systems are vital to guarantee the integrity, quality, and safety of agrochemical products.

Track and trace systems facilitate the monitoring of products throughout the supply chain, from manufacturer to final distribution. By implementing these systems, the industry can address challenges such as ensuring compliance with rigorous regulations, preventing the spread of counterfeit products, efficiently managing the return and reuse of IBC, and enhancing operational efficiency.

Beyond compliance and counterfeiting fighting, traceability solutions protect the consumer by ensuring the responsible use of agrochemicals but also strenghten the industry’s resilience against supply chain disruptions.

Recognizing and embracing the advantages of traceability is crucial to uphold the integrity and sustainability of the industry amidst increasing demands and challenges.

Business application

Download our User Case on Track and Trace systems implementationWHAT OPTEL TRACEABILITY SOLUTIONS CAN DO FOR YOUR BUSINESS

We can support you in every step of your track and trace implementation process

Interested in this solution?

Track & Trace systems for AgrochemicalsRelated Solutions

Anti-counterfeiting

Stop counterfeiting, protect your brand and gain greater consumer confidence

Serialization

Serialization is the first step in the traceability journey. OPTEL delivers scalable pharma solutions for global compliance and end-to-end visibility.

Aggregation

Aggregation takes you beyond unit-level traceability to see the whole picture

Inventory Tracking and Planning

Manage your inventory like never before: real-time visibility on asset inventory levels, geolocation and expired date tracking

Optchain Solution

OPTEL’s Intelligent Supply Chain is a powerful traceability platform that digitizes supply chains from end to end.

Reusable Packaging Management

Trace and monitor your reusable assets from manufacturing to end user and back

Carbon Tracking

Measure and track your environmental footprint across your supply chain

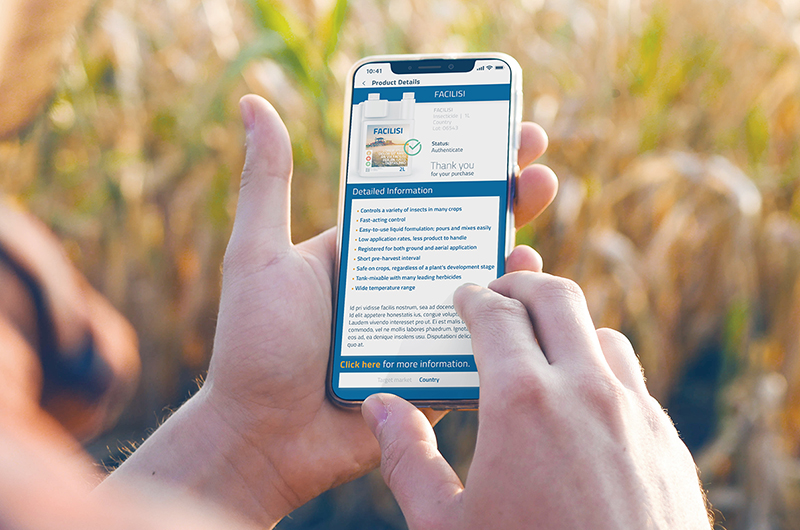

Product Authentication

Authenticate any product, any time, anywhere for total consumer confidence and regulatory compliance