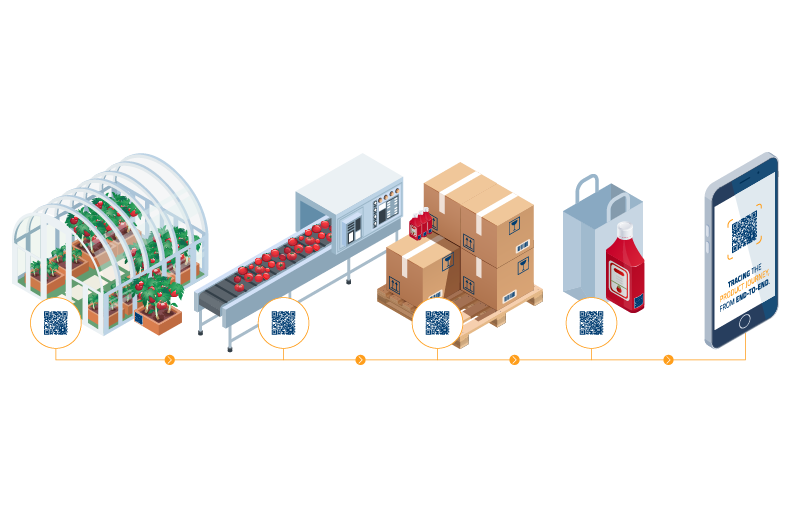

Traceability has evolved from being a desirable feature to an essential requirement in many industries. While it may initially appear daunting, finding the right partner will help you successfully achieve your traceability goals and enhance your overall business performance.

Reach out to OPTEL today to discover our innovative approach to traceability and experience the unparalleled capabilities of our cutting-edge technology.