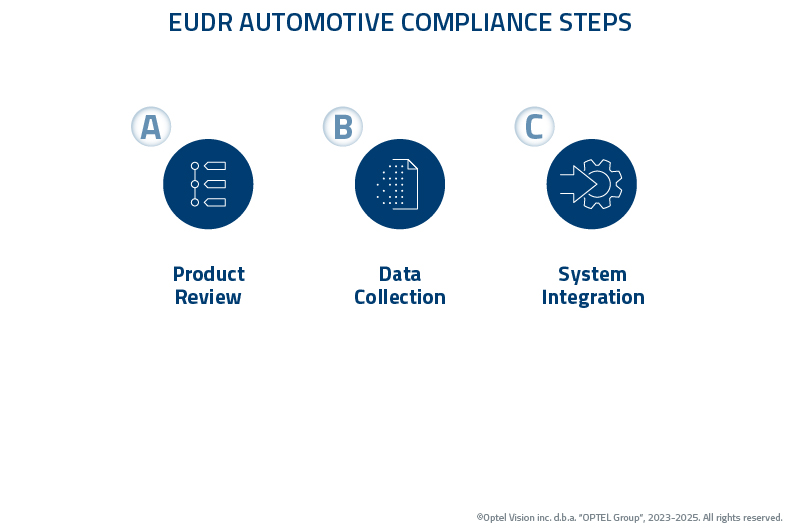

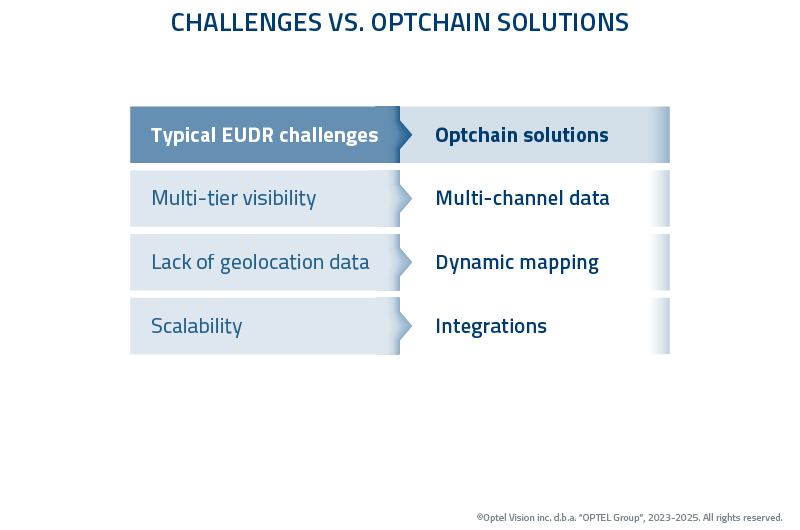

The European Union Deforestation Regulation (EUDR) presents unprecedented compliance challenges for automotive manufacturers. Automotive companies must establish comprehensive due diligence systems to trace deforestation-risk materials throughout their complex, multi-tier supply chains.

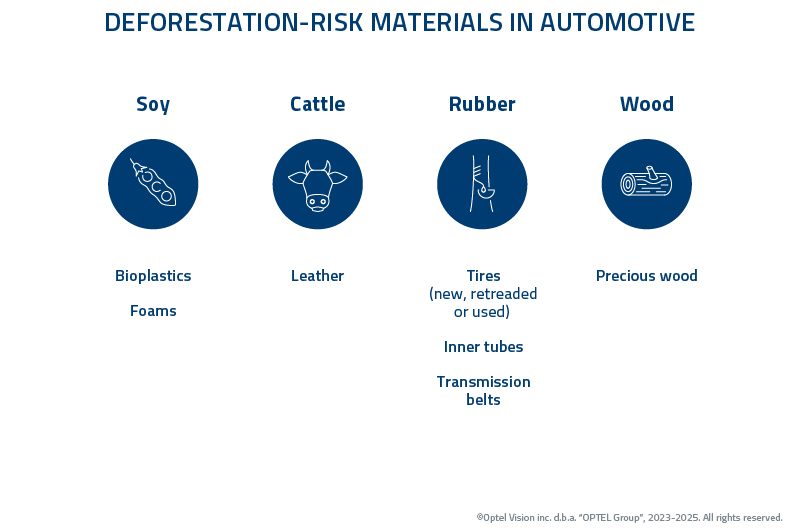

Automotive manufacturers face unique compliance requirements due to their extensive use of natural rubber, leather, wood, and soy-based components. The regulation prohibits placing products on the European market that originate from lands deforested, requiring precise geographic documentation and supply chain transparency.

This checklist provides automotive industry stakeholders with actionable steps to achieve EUDR compliance while maintaining operational efficiency and competitive advantage.