35

Anos de Experiência

6000

Sistemas Instalados em Todo o Mundo

25B

Bilhões de Produtos Rastreados por Ano

24 / 7

Suporte Técnico Internacional

96 %

Nível de Satisfação de

DESCUBRA NOSSA SOLUÇÃO DE RASTREABILIDADE DE PONTA A PONTA

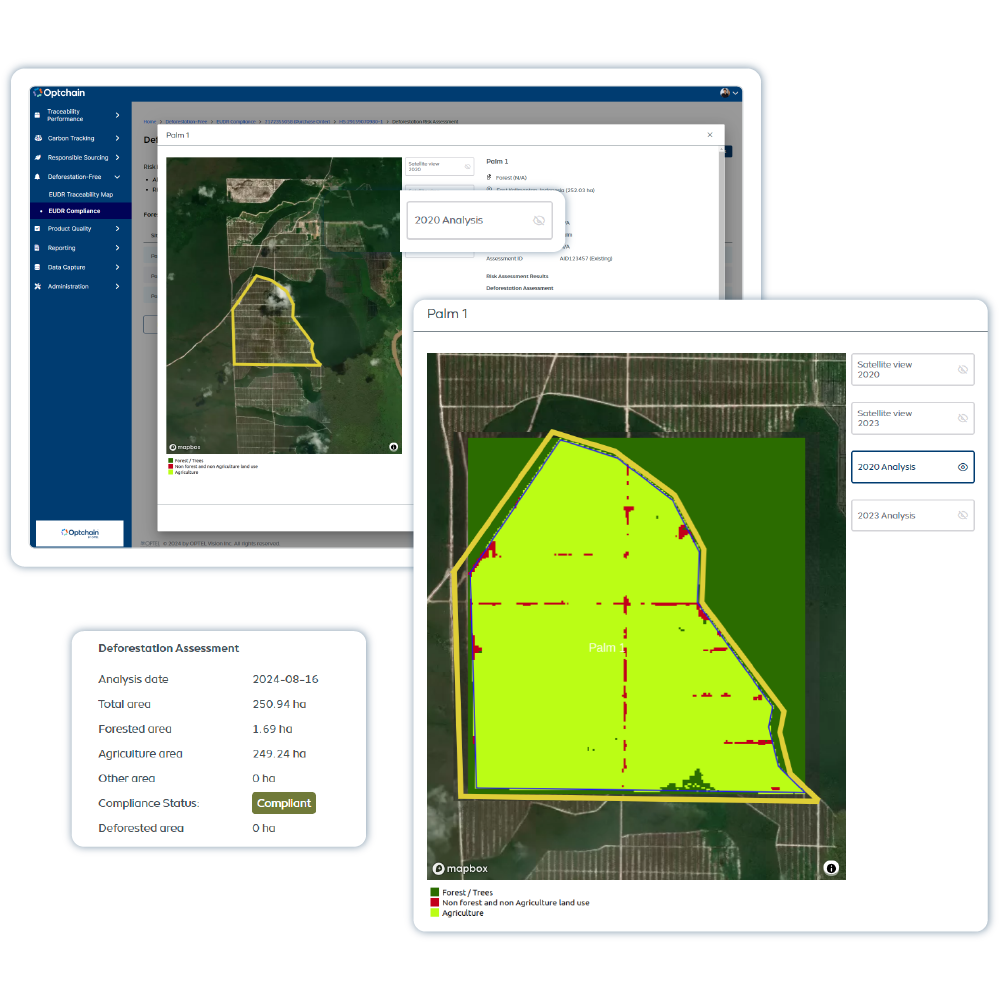

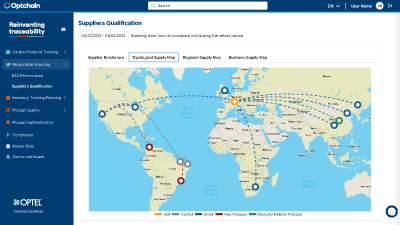

Rastreabilidade ESG

Optchain é uma plataforma de sustentabilidade da cadeia de suprimentos que garante conformidade ESG e visibilidade total do ciclo de vida dos produtos. Seus módulos cobrem regulamentações como EUDR, DPP, CBAM, CSRD, CSDDD e mais. O Optchain também rastreia as emissões de carbono nas cadeias de suprimentos, ajudando as empresas a medir, monitorar e reduzir sua pegada ambiental de acordo com os objetivos de sustentabilidade.

Descubra o Optchain

Sistemas de Rastreamento e Inspeção

Soluções hardware de serialização e agregação para otimizar o desempenho da linha e garantir excelência em track & trace com sistemas de visão integrados à IA.

Descubra o TrackSafe

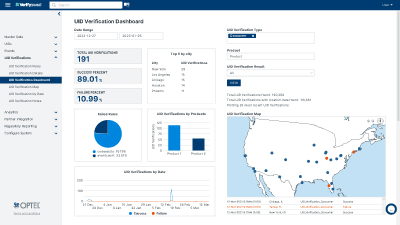

Solução de Integridade da Cadeia de Suprimentos

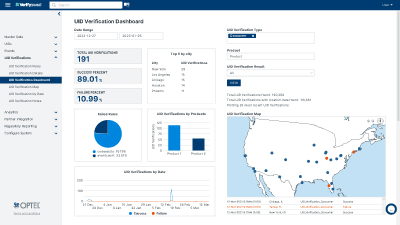

VerifyBrand™ é um software de serialização e rastreabilidade real que garante conformidade com regulamentações, aprimora a proteção da marca, autentica produtos e otimiza o estoque.

Descubra o VerifyBrand™