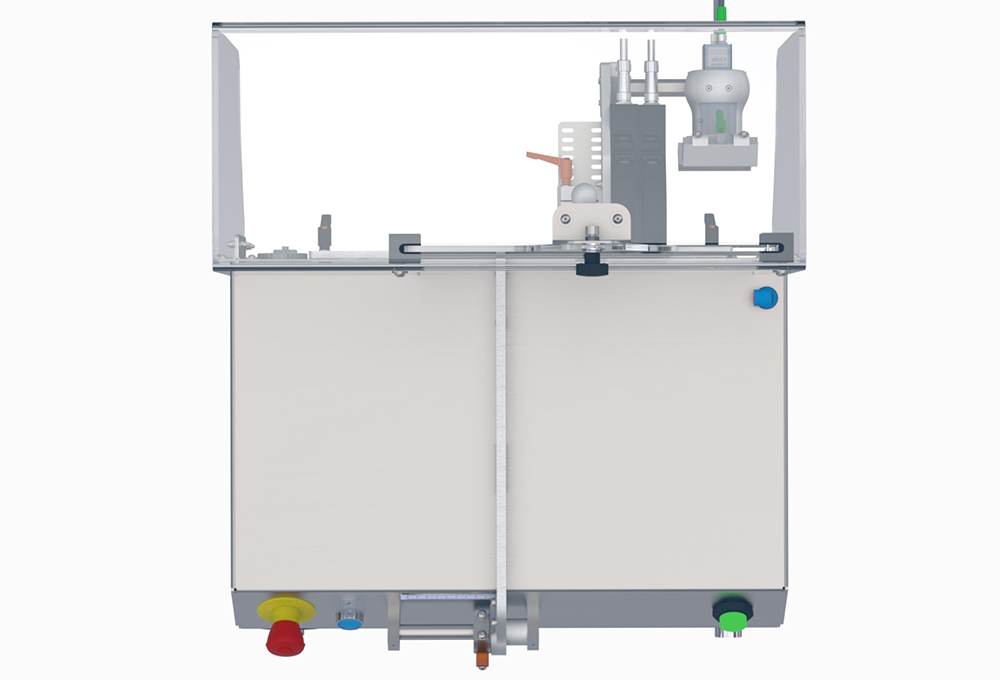

SEMI-AUTOMATED PRINT STATION (SAPS)

Sind Sie auf der Suche nach einem schlüsselfertigen, vollständig autonomen System für die Kleinserienproduktion? Die Semi Automated Print Station ist die richtige Lösung für Ihr Unternehmen. Die Semi Automated Print Station ist konzipiert, um Ihre Schachteln effizient zu drucken und zu prüfen, sodass eine genaue Serialisierungsidentifizierung gewährleistet wird.

Zusätzlich kann das System ein großes Sortiment an Schachtelgrößen verarbeiten. Verstellbare Führungen helfen dabei, die Schachteln zu positionieren und gewährleisten die genaue Ausrichtung der gewünschten Druckfläche.

Die neue Semi-Automated Print Station erhöht die Produktionsgeschwindigkeit, da beide Hände dazu verwendet werden können, die Schachteln zu handhaben.

ECKPUNKTE

- Verbesserte Ergonomie

- Einfache Benutzeroberfläche

- Einfache Lösung für kleine Mengen

- Kompatibilität mit dem LineMaster™ von OPTEL, um die Aggregation hinzuzufügen

SCHLÜSSELVORTEILE

- Erhöhung der Produktionsgeschwindigkeit

- Völlige Autonomie

- Handhabung zahlreicher Schachtelgrößen

- Tragbare Einheit

- Einfache Installation und einfacher Betrieb

- Minimale Schulung erforderlich

WEITERE INFORMATIONEN FINDEN SIE IN DEN UNTEN VERFÜGBAREN PRODUKTINFORMATIONEN

Datenblatt zur Semi-Automated Print Station herunter

Laden SieERGÄNZENDE LÖSUNGEN

Aggregierung

Aggregation führt Sie über die Rückverfolgbarkeit auf Einheitsebene hinaus, um das gesamte Bild zu sehen

Serialisierung

Die Serialisierung ist der erste Schritt auf dem Weg zur Rückverfolgbarkeit

Vision-Systeme

Die Bildverarbeitungssysteme von OPTEL tragen zur Gewährleistung von Qualität und Sicherheit bei