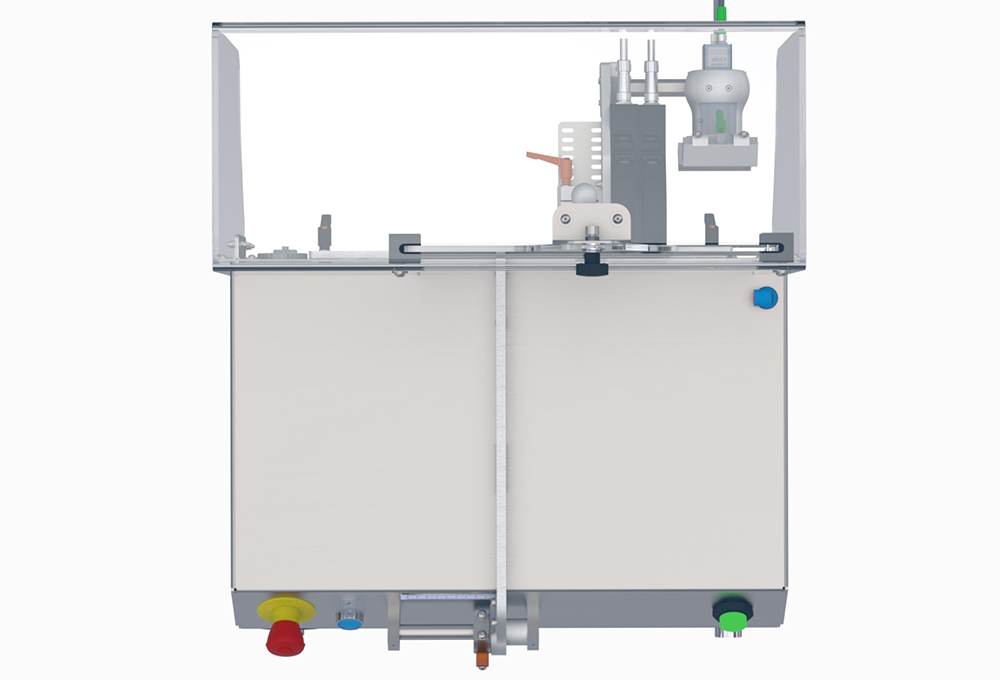

THE SEMI-AUTOMATED PRINT STATION (SAPS)

Looking for a turnkey, fully autonomous system for low volume production? The Semi-Automated Print Station is the right solution for your business. It is designed to efficiently print and inspect your cartons to ensure accurate serialization identification.

In addition, the unit can handle a wide range of carton sizes. Adjustable guides help position the cartons and ensure proper alignment of the desired print area.

The new Semi-Automated Print Station increases the production speed since both hands can be used to manipulate the cartons.

KEY FEATURES

- Enhanced ergonomy

- Easy user interface

- Simple solution for low volume

- Compatible with OPTEL’s LineMaster ™ to add aggregation

KEY BENEFITS

- Increase production speed

- Fully autonomous

- Handle a wide range of carton sizes

- Portable unit

- Easy to install and operate

- Minimal training required

FOR MORE INFORMATION, PLEASE REFER TO THE PRODUCT DATASHEET

Semi-Automated Print Station Datasheet

DownloadRelated Solutions

MEET OUR EXPERTS